Nesting Top Camera Oscillating Knife Cutting Machine for Garment, Sofa, Car seat

Features:

1. High speed: Only need 80 seconds to finish one set of car foot mat., only need 6 minutes to finish one set of car cushion mattress.

2. High efficiency: don't need any die mold, or die mold cutting machine, this machine can press mark, cutting and molding on soft material such as leather, carton etc. Save much labor and cost.

3. High flexibility: self-developed tool quick change mold, equipped with different blades for cutting different materials, suitable for cutting foam materials of different softness.

4. Low cost Operation: Equipped with a tool quick-change module, independently developed a tool quick-change device, to achieve rapid replacement of more than ten kinds of tools. The cutter can be switched freely, which is suitable for all kinds of cardboard without changing the material of the cardboard box cutting machine. one machine can do design, cutting instead of manual design and cutting, save labor, and material wastage cost.

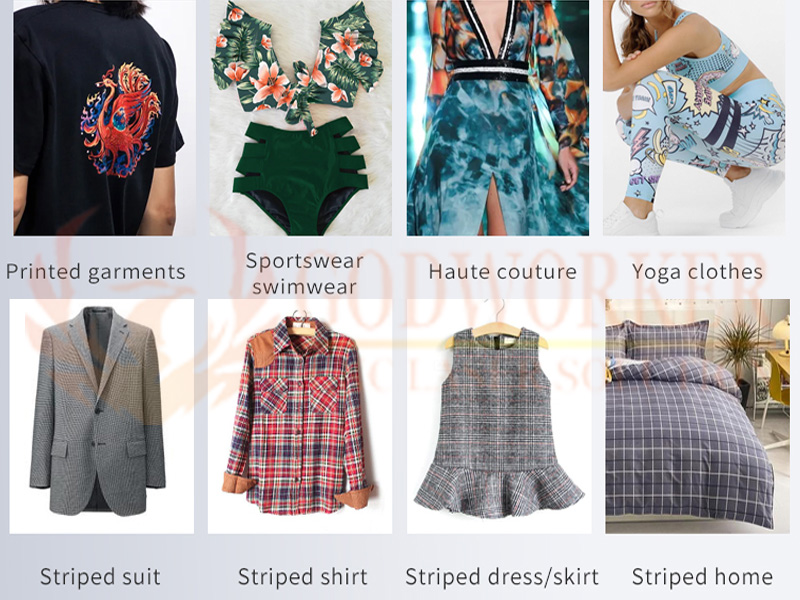

5. Wide application: This machine can cut leather, PU, fiber, EVA, XPE, sponge cladding, composite cladding, Sponge+drape+composite leather, PVC foot mat, paper, carton, plastic board etc. Soft material.

6. Good performance: adopt Taiwan HIWIN Linear Rail + helical gear rack, low noise, accurate transmission. Long lifespan and high precision.

7. High cutting accuracy: imported high-precision racks are used to make it easier to cut foams with different softness, ensuring higher cutting accuracy

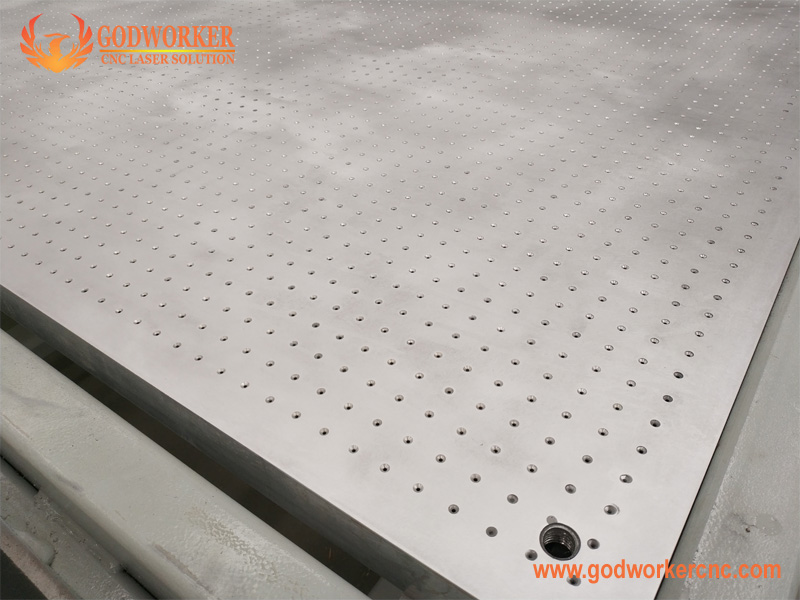

8. Durable and non-deformable: honeycomb aluminum workbench, vacuum adsorption design, super air, strong suction (partition adsorption, no longer adsorption of small samples) is difficult to cut).

9. CCD: High precision camera, professional for positioning for print materials. Automatic and precise.

|

Model |

GW-1625NA |

GW-1630NA |

GW-1650NA |

|

Working area |

2500×1600mm |

3000*1600mm |

5000*1600mm |

|

Machine size (mm) |

3550×2330×1550mm |

3360*2330*1550mm |

5560*2330*1550mm |

|

Rated power |

15KW |

||

|

Fixed mode |

auto conveyor feeding system |

||

|

Multi-function head |

Oscillating knife cutting head ( Circle knife head / Pneumatic head / Punch head ) |

||

|

Tool configuration |

Multiple cutting knives |

||

|

Safety device |

Using infrared sensors, responsive, safe and reliable. |

||

|

Cutting speed |

200-1500mm/s(according to different cutting materials) |

||

|

Cutting thickness |

≤100mm(according to different cutting materials) |

||

|

Repeated accuracy |

≤0.1mm |

||

|

Machenical Precision |

Max. 0.02mm |

||

|

Driving system |

Delta servo motors + drivers (Panasonic servo motor for option) |

||

|

Transmission system |

Helical gear rack + HIWIN linear rail (X,Y axis 20mm) |

||

|

Control system |

Ruida 6584G + touch control panel |

||

|

Vision system |

Camera |

||

|

Support format |

AI, PLT, DXF, CRD, etc |

||

|

Capacity |

4GB |

||

|

Voltage |

380V + 220V, 50/60Hz |

||

|

Vacuum pump |

9kw vacuum pump |

||

|

Packing size |

3700*2270*1650mm |

3750*2270*1650mm |

5850*2270*1650mm |

|

Weight |

1300KG |

1500KG |

2000KG |

Vacuum table: Adopt sophisticated aluminum sophisticated table design, platform width can be customized size, theoretical length is unlimited; vacuum suction design, software can choose to control 8 suction area.

Imported Germany fiber mat that durable, good permeability, and stable shape.

Pneumatic pressure plate: assitance for auto feeding materials, special for multi layers fabric / textile.

Vacuum Pump: Adopt strong power 9KW air vacuum pump for fixing materials while machine cutting materials.

Safety Sensor: Y axis has 2 sets infrared sensor to protect operator or other human body safety.

Control cabinet: Control board, drivers, breakers.

Feeding bracket: loading roll materials, more easy conveyor.

Auto Lubracation: Regular automatic lubrication guide rail.

A: We are a factory and the one manufacturers of vibrating knife cutting machines in North of China with about 10 years experiences in this field.

Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experiencedprofessional design team, we can give you our professional suggestions according to your requirements and design a cost-effective machine for your needs.

Q: What is the difference between your product and the laser cutting machine?

A: 1. Our products are cut with vibrating blades, no laser, no pollution, and create a good working environment for workers.

2. Blade cutting can ensure the edge of material cutting smooth without burning.

Q: Does your price have a discount for dealers?

A: Yes, we have a favorable policies for dealers. Please tell me your order quantity or annual purchase quantity. The price will be adjusted according to the order quantity. For details, please consult our sales staff.

Q: How is your after-sales policies?

A: 1. The machine warranty is 12 months after shipment date. During the warranty period, the main accessories(except the wearing parts) are replaced free of charge because of the quality problems under the normal operation. Others, under improper operation need to pay the parts cost and freight.

2.We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical support, online support, Engineers available to service machinery overseas.

3. Inquiries are typically answered within 24 hours.

Q: Can you provide ODM and OEM services?

A: Yes, our R&D team with an average of 10 years experiences, the ODM&OEM service are satisfied with our customers.

-

Brand:Godworker

-

Model:GW-1625N;GW-1630N;GW-1625NA;GW-1630NA;GW-1650NA

-

MOQ:1 set

-

Payment Terms:T/T 30% deposit advance, 70% payment before shipment

-

OEMYes